Remedial review: Effective treatment of Benzene, MTBE at petroleum sites

Review evaluates REGENESIS product PetroFix as a solution for difficult-to-close gasoline service station sites in the petroleum market.

Photo bythe U.S. Department of Energy

The U.S. Environmental Protection Agency (EPA) reports that as of September 2020, there have been 559,000 releases from underground storage tank (UST) sites. Although many of these sites have been remediated and closed, there are still 62,000 open sites that require attention. These sites are either undergoing remediation or have been identified as needing remediation for one or more contaminants of concern (COCs).

The primary COCs that require remediation at petroleum sites include benzene, toluene, ethylbenzene, xylenes, polycyclic aromatic compounds (PAHs), methyl-tertiary butyl ether (MTBE), and total petroleum hydrocarbons (TPH). Benzene and MTBE are particularly important due to their low cleanup levels, based on EPA's Maximum Contaminant Levels (MCLs) in drinking water. The MCLs for benzene and MTBE are 5 and 20 micrograms per liter (ug/L), respectively.

Most of the 62,000 open sites have undergone remediation using various methods, such as fixed mechanical systems, in situ injections, or soil excavation, alone or in combination. While these methods have successfully reduced the bulk of the contaminant mass in soil and groundwater, they have not led to regulatory closure in most cases.

The reality is that many of these sites are challenging to remediate fully, primarily because the methods used have been unable to reduce and sustain groundwater concentrations below the part-per-billion-level action levels required for the most risk-sensitive COCs, such as benzene and MTBE.

In the past, most applied remedial technologies and approaches met an asymptotic remediation boundary condition that could not be crossed in a timely manner. Consequently, there remain "hotspots", relatively limited in aerial extent, requiring further remediation. These hotspots usually cover a few hundred to a few thousand square feet of surface area, requiring only a single well or two to reach the remediation targets.

PetroFix Applications Enable Regulatory Closure at Challenging Hydrocarbon Sites

REGENESIS® launched PetroFix® in 2018 as a solution to the technical challenge of addressing difficult-to-close gasoline service station sites in the petroleum market. Specifically designed and formulated for the petroleum hydrocarbon market, PetroFix is a highly effective, easy-to-apply, and cost-efficient tool for engineering consultants to remediate these sites and obtain regulatory closures (a.k.a., No Further Actions or NFAs). PetroFix has been applied to treat petroleum hydrocarbon contaminants at over 746 sites worldwide to date.

The colloidal activated carbon (CAC) amendment is easily applied to the contaminated zone through standard direct-push drilling equipment, injection wells, or UST basins. These treatments create an immense surface area coated with 1 to 2-micron-size activated carbon particles.

PetroFix treatments promote rapid sorption kinetics, immediately and sustainably eliminating petroleum COCs from the dissolved phase. Laboratory and field studies have confirmed that these contaminants are not only sorbed but also biodegraded in the presence of PetroFix.

PetroFix contains inorganic electron acceptors such as sulfate and nitrate, which promote the safe biological transformation of COCs to non-toxic end products. The product is supported by the PetroFix Design Assistant ™ a user-friendly online resource which provides consultants with sophisticated design tools to calculate product dosing requirements and guide application designs.

Performance Review

A remedial performance review following PetroFix injection was completed for 11 sites in the U.S. and Canada, where sufficient performance monitoring data for benzene and MTBE could be readily obtained. Project sites were in Ohio, Indiana, West Virginia, Florida, Colorado, and Washington in the U.S. and Alberta, Canada.

The near-surface geology at these sites was comprised of unconsolidated soils ranging from sand & gravel to clay and engineered fill. Amendments were delivered into the subsurface at these sites using standard direct-push injections driven by a hydraulic percussion drill rig. This performance review focuses on benzene and MTBE since, in most cases, one or both were the only groundwater COCs necessitating cleanup.

All sites have undergone a quarterly performance monitoring program. Of the 24 wells included in this review, 18 have groundwater sampling data available through 12 months. Three wells have two years of performance monitoring data. A subset of these sites was also sampled at one (number of sites [n] = 7) and two months (n=5).

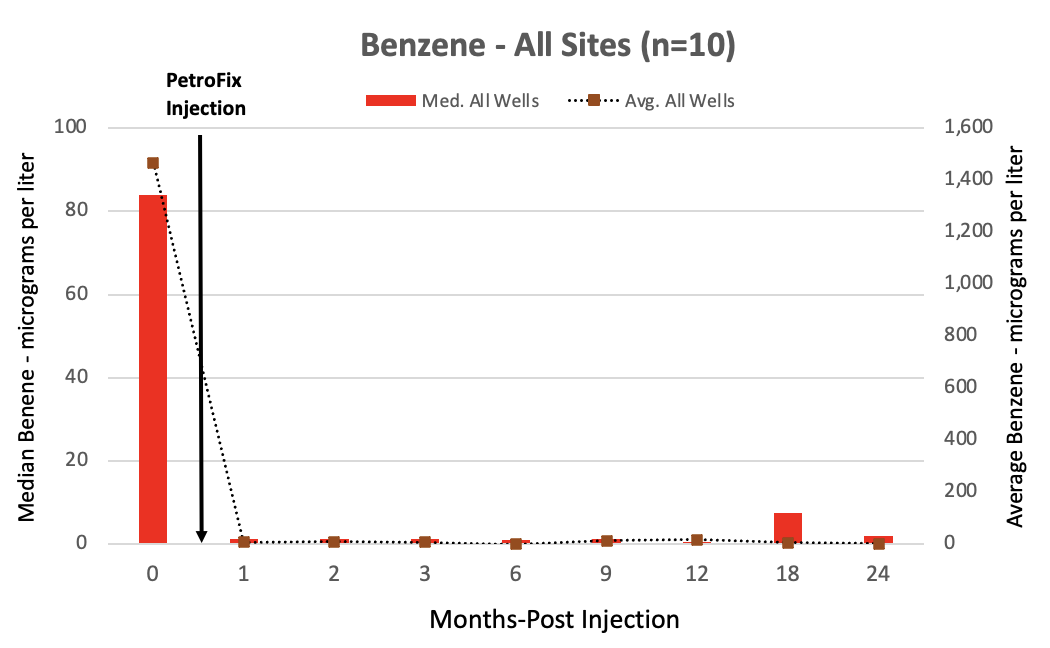

Results: Benzene

Benzene performance data were obtained from 22 wells at ten sites where PetroFix applications were completed. Following PetroFix injection, the median benzene concentration was reduced from 84 ug/L to below detection limits (nominally 1-2 ug/L) by the first quarter monitoring event (i.e., approximately three months post-injection). These results were sustained through the various performance monitoring periods. Eighteen of the 22 wells have performance data available through 12 months, and three wells through two years of monitoring. Average results, although much higher, show similar trends.

Figure 1. Median and average benzene concentrations in groundwater obtained from site performance monitoring wells following PetroFix injections. The median results are plotted relative to the left vertical axis, and the average results are plotted relative to the right vertical axis.

Figure 1. Median and average benzene concentrations in groundwater obtained from site performance monitoring wells following PetroFix injections. The median results are plotted relative to the left vertical axis, and the average results are plotted relative to the right vertical axis.MTBE

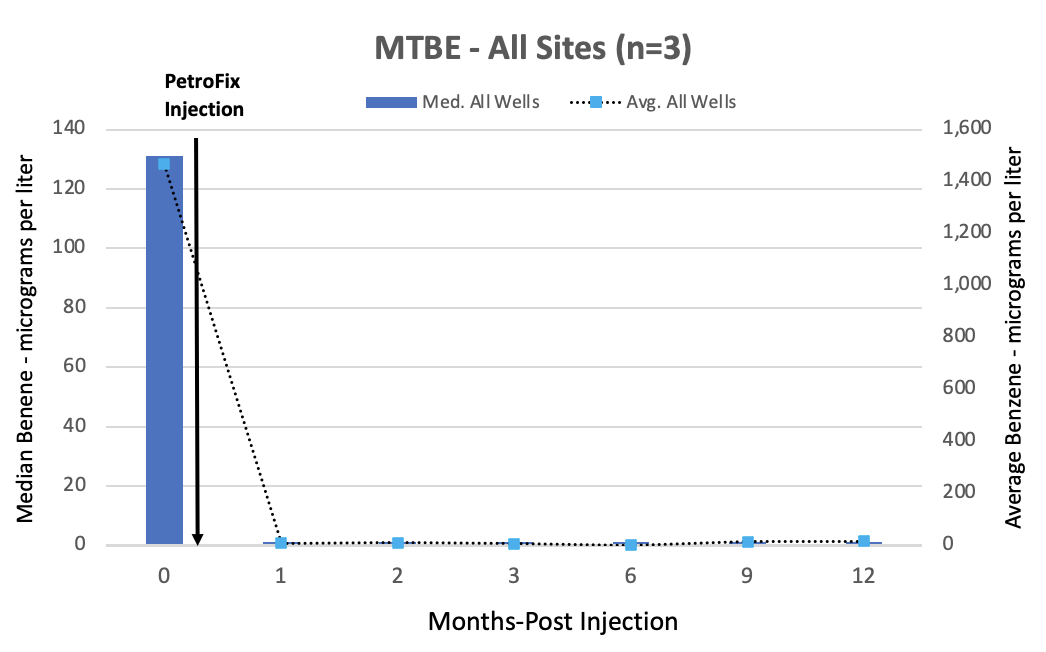

MTBE performance data were obtained from four wells at three sites where PetroFix applications were completed. Following PetroFix injection, the median benzene concentration was reduced from 84 ug/L to below detection limits (nominally 1-2 ug/L) by the first quarter monitoring event (i.e., approximately three months post-injection). These results have been sustained through the completed sampling events. Two sites have performance data available through 12 months and one site through six months. Average results, although much higher, show similar trends.

Figure 2. Median and average MTBE concentrations in groundwater obtained from site performance monitoring wells following PetroFix injections. The median results are plotted relative to the left vertical axis, and the average results are plotted relative to the right vertical axis.

Figure 2. Median and average MTBE concentrations in groundwater obtained from site performance monitoring wells following PetroFix injections. The median results are plotted relative to the left vertical axis, and the average results are plotted relative to the right vertical axis.Conclusion

The use of PetroFix has demonstrated the complete elimination (approximately 100 percent) of benzene and MTBE in groundwater at 11 sites across the U.S. and Canada, on average. These treatments have met the performance objectives, often meeting difficult-to-obtain MCLs, leading to regulatory closure at several sites. Other sites are pending closure if monitoring trends continue for the defined performance monitoring period (i.e., typically one to two years post-application).

These results show that PetroFix is an effective tool for quickly reducing the risk-sensitive benzene and MTBE concentrations in groundwater and obtaining regulatory closures in short order for long-open sites.