Results document the biodegradation of contaminants from colloidal activated carbon

The following white paper provides an abbreviated overview of two laboratory experiments and a fieldwork demonstration that showed evidence for the biodegradation of contaminants from CAC.

The colloidal activated carbon (CAC) technologies developed by REGENESIS, PetroFix® and PlumeStop®, are often paired with biostimulating electron acceptors or donors to destroy adsorbed contaminants. Early laboratory and field research with our CAC-based technologies has shown the ability of bacteria to fully mineralize adsorbed contaminants and increase in population in the presence of CAC and electron acceptors or donors added to the system even though the CAC has a tiny diameter (1–2 micrometers in diameter). In the case of PetroFix, soluble electron acceptor salts are included to provide nitrate and sulfate, favorable electron acceptors used for biostimulation of hydrocarbon biodegradation.

We hypothesize that biostimulated bacteria form biofilms on the PetroFix or PlumeStop surfaces coating the soil grains, and this close contact allows for contaminant destruction. Concentrated contaminants make for a ready food source for bacteria to grow. Recent work by the University of Waterloo’s Bill McLaren, as presented in a poster at Battelle in 2022, showed that the presence of activated carbon, even small carbon particles, appeared to enhance the rate of anaerobic biodegradation of petroleum hydrocarbons 1.

The following white paper provides an abbreviated overview of two laboratory experiments and a fieldwork demonstration that showed evidence for the biodegradation of contaminants from CAC. Each section has links to the original information. Since PlumeStop and PetroFix use the same size of activated carbon and are delivered similarly into the subsurface, these results are considered interchangeable between the two CAC technologies.

Biodegradation Bench Scale Study

Full Contaminant Mineralization in the Presence of CAC

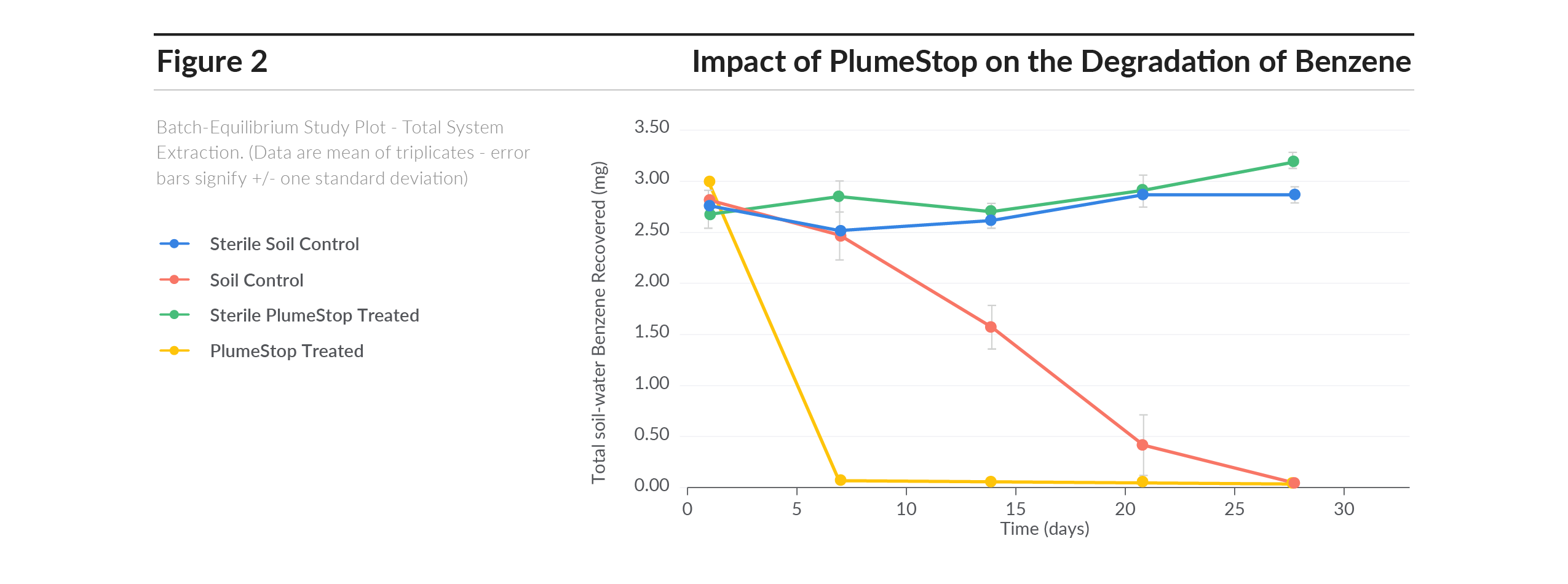

Early in the development of CAC, a laboratory batch study was performed to evaluate the post-sorption biodegradation of contaminants. A series of batch-equilibrium samples were prepared in 8 oz amber serum bottles that contained 10 g of soil and 70 mL of water spiked with 3 mg of benzene. Oxygen was used as the electron acceptor from the headspace of the bottles (~2/3 of the bottle was headspace). Sets of bottles were prepared to test different conditions:

- A sterile control – sterilized soil and benzene;

- A live control – soil and benzene;

- CAC treatment (PlumeStop) – soil, benzene, and PlumeStop; and,

- A Sterile CAC treatment (PlumeStop) – sterile soil, benzene, and PlumeStop

Bottles were sampled destructively in triplicate on days 1, 7, 14, 21, and 28. Benzene was quantified in the aqueous phase, and a mass-balance extract of all contents from the bottle (extracting benzene from water and soil into hexane) was also performed.

In less than seven days, the PlumeStop bottles (line shown in yellow in Figure 2 ) showed rapid elimination of benzene to non-detect concentrations from soil and groundwater. Mineralization likely was even faster than the 7-day mark when the first sacrificial batch was taken. Comparatively, the soil-only control (no PlumeStop) achieved only a 12.5% reduction by day 7. Sterile controls showed no destruction and no laboratory loss of contaminants.

For further information on the study, please access it here:

PlumeStop Technical Bulletin 3.1 or through a webinar co-presented with Microbial Insights showing a deeper analysis of the research entitled “Demonstrating Contaminant Biodegradation in Conjunction with PlumeStop Liquid Activated Carbon.”

Image of a flow-through tank in operation. Dark areas show PlumeStop in the more conductive area and start to diffuse into the lower k zones (lighter color bands).Flow-Through Tank Study

Image of a flow-through tank in operation. Dark areas show PlumeStop in the more conductive area and start to diffuse into the lower k zones (lighter color bands).Flow-Through Tank Study

Enhanced Microbial Activity

Professor Tom Sale of Colorado State University led a tank study funded by the Strategic Environmental Research and Development Program (SERDP).

In the original study, tanks with alternating layers of high- and low-conductivity soils were used to simulate the storage and subsequent release of TCE from low permeability zones while testing the sustained treatment effectiveness of various remedial strategies that included permanganate and other combinations of electron donor and anaerobic culture. T

he results of this study provided a much greater understanding of treatment effectiveness and the phenomenon of back diffusion.

REGENESIS worked with Tom Sale and Kevin Saller, pH.D. (then with CDM) to create a similar flow-through tank system to evaluate the distribution capability of PlumeStop. Other biological parameters were also taken during this test. Four stainless steel tanks with glass panes were packed with nine alternating layers of silt and sand. Once complete, the tanks were flushed with TCE-saturated water, flushed clean, and then given a continuous flow of anaerobic water throughout the experiment.

PlumeStop, lactate and other amendments we added >103 days into the experiment. Effluent samples were collected throughout the experiment, and water and soil samples were sent to Microbial Insights Inc. at the end of the experiment for qPCR analysis.

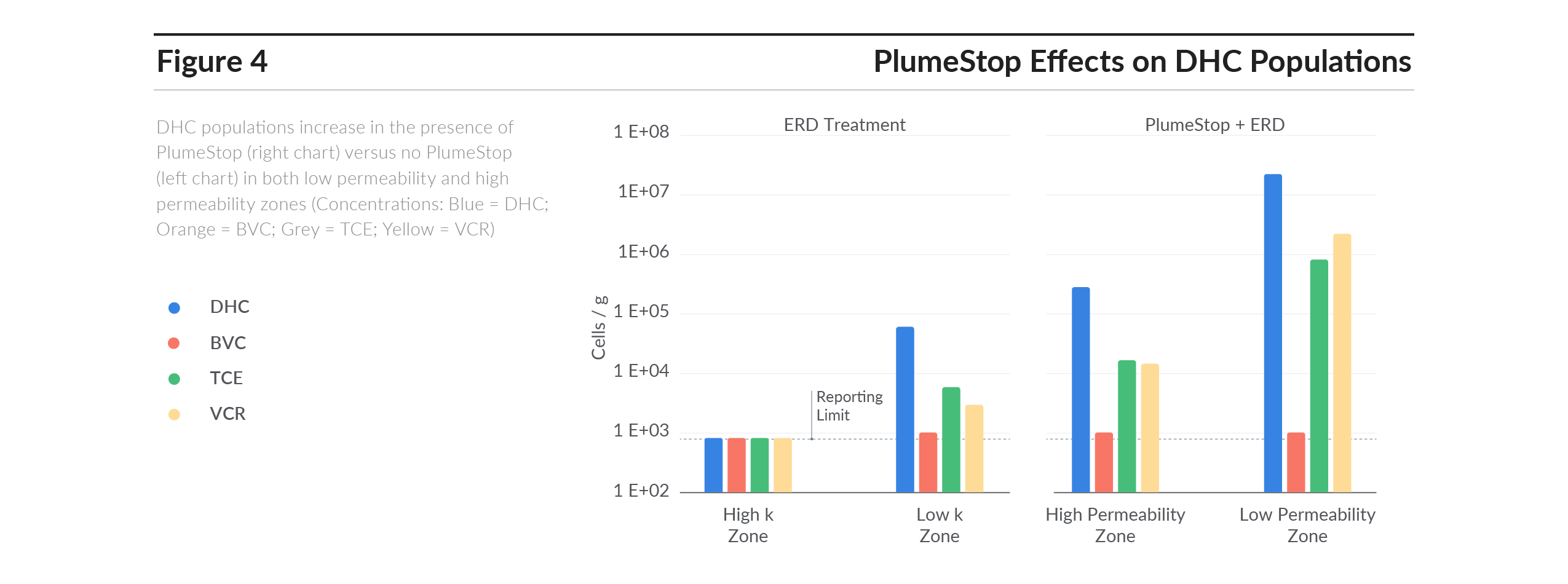

PlumeStop Effects on DHC Populations

The experiment successfully showed PlumeStop distribution in high K zones and even penetration into low k zones. Additionally, relevant to this discussion, the Dehalococcoides (DHC) populations and functional genes, including TCE reductase (TCE and vinyl chloride reductases (VCR and BVC), increased at least 1 to 2 orders of magnitude compared to the ERD treatment column without PlumeStop (see figure 4). Effluent concentrations showed between 90 and 99.9% TCE mineralization in the tanks with PlumeStop.

These results indicate that biofilms grow within and around the CAC-coated soil, increase microbial mass, and degrade contaminants. The results provide another experiment with the biodegradation of contaminants from CAC.

The full description of the experiment can be found here:

A Solution to the Problem of Back Diffusion

Field Beta Trials with PetroFix

Field Beta Trials with PetroFix

Increased Microbial Activity in the Presence of PetroFix

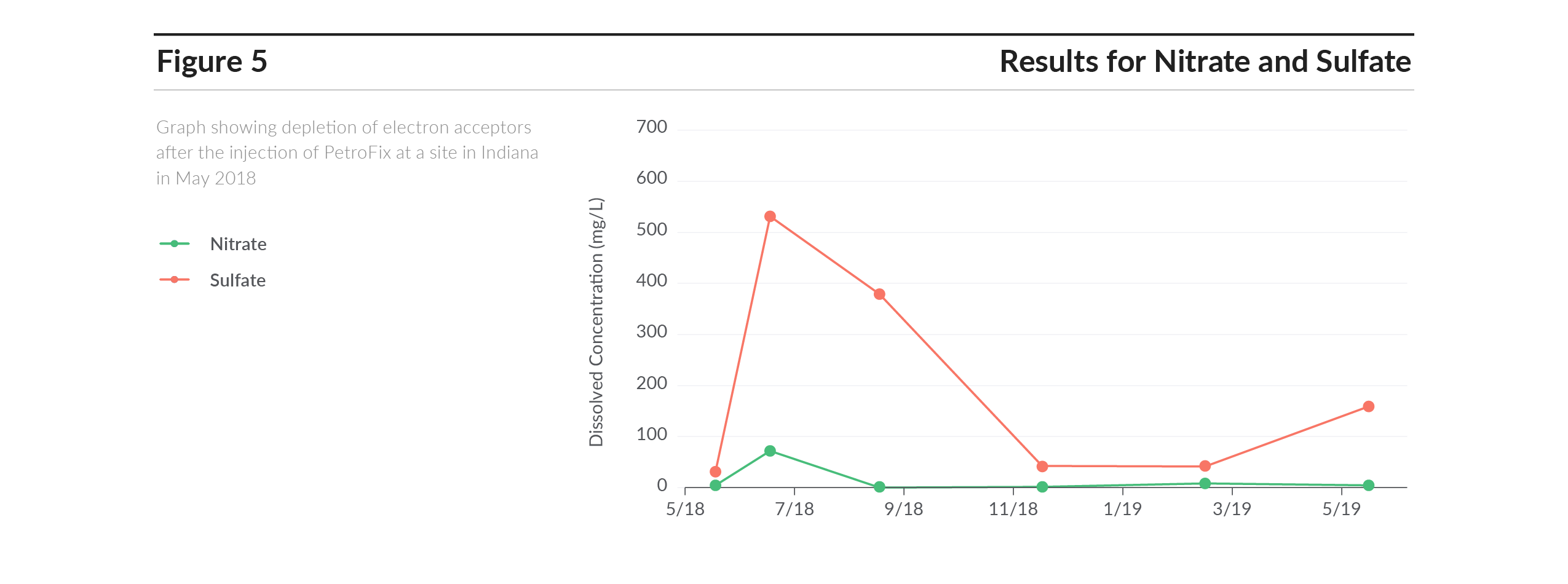

In the field, multiple lines of evidence are required to show ongoing biodegradation after adsorption. The decreasing contaminant concentrations observed following PetroFix injection, is insufficient proof because rapid contaminant adsorption onto the activated carbon obfuscates contaminant destruction. A stronger line of evidence is the utilization of added nitrate and sulfate in the sequence predicted by anaerobic biodegradation (nitrate first, sulfate second). In Figure 5 , the correct order of electron acceptor utilization is observed at an early PetroFix beta test site in Indiana.

Another line of evidence is to measure an increase in microbial populations and gene targets post-PetroFix application (see figure 6). Microbial population growth is observed post-application, which can be attributed to the beneficial microbial populations having access to adsorbed contamination to fuel their growth. The decrease of electron acceptors following addition, combined with increasing microbial populations is strong evidence for biodegradation.

For additional information on the Indiana Beta test site, please access the following PetroFix case study:

REGENESIS® offers remediation professionals a suite of innovative technologies and services to treat a wide range of contaminants, including petroleum hydrocarbons, chlorinated solvents, PFAS and metals, via enhanced bioremediation, bioaugmentation, in situ chemical oxidation, reduction (ZVI), sorption, desorption, immobilization and vapor intrusion mitigation.

.webp?height=200&t=1720617286&width=200)