Sustainable, immediate and low-cost PFAS source treatment

Pilot studies incorporating SourceStop horizontal barrier treatments demonstrate elimination of PFAS leaching within hours of application

Field-scale pilot studies for the in situ treatment of soils at PFAS source zones were recently completed at firefighting training areas on two aviation sites where PFAS-containing AFFF (i.e., aqueous film-forming foam) was historically discharged. The PFAS source treatments applied site-specific amendment blends of SourceStop™ colloidal activated carbon (CAC) and powdered activated carbon (PAC). SourceStop, a micron-scale aqueous carbon suspension, was emplaced as a horizontal PFAS barrier at the base of the target treatment zones. As published in a previous Remediation Technology article, laboratory studies have shown that SourceStop prevents PFAS leaching with >10x more effectiveness than PAC.

Both pilot tests demonstrated PFAS soil leachate concentrations were reduced by >99% within hours following the source zone treatments and at one of the sites, six-month post-treatment monitoring results showed reduction to non-detect levels. Post-application sampling is planned for the second site, with similar results anticipated.

Pilot Test Site Locations

PFAS source areas at two U.S. aviation facilities were selected for implementation of the field pilot testing program.

- Site 1 - Grayling, Michigan (MI)

- Site 2 - Everett, Washington (WA)

At both sites, repeated AFFF discharges had left high concentrations of PFAS in the shallow soils leaching to the underlying groundwater.

An approximate 225-square-foot (ft) area and a 10-ft vertical mixing zone were demarcated at each site, and utilities were cleared for the SourceStop pilot test (Figures 2 and 3). The pilot test areas were placed within more extensive PFAS source zones and only partially encompassed them.

The near-surface soils were predominantly sands, overlain by a topsoil layer. Groundwater was encountered at approximately 14 feet and 15.5 ft depth at Site 1 and Site 2, respectively. Therefore, these treatments were fully contained within the vadose zone.

Figure 1. Aerial view showing Site 1 treatment area and sampling locations.

Figure 1. Aerial view showing Site 1 treatment area and sampling locations.Baseline Soil and Groundwater Sampling

Pre-treatment soil sampling was performed by homogenizing soils cores collected at 0 to 5 ft below ground surface (bgs) and 5 to 10 ft bgs in three boreholes advanced within each target treatment area, totaling six samples per site. At Site 2, following the same procedures, a fourth boring was advanced outside the treatment area as a control.

Leachate extracts were prepared from these samples using U.S. EPA's SW-846 Test Method 1312: Synthetic Precipitation Leaching Procedure (SPLP), subsequently analyzed for PFAS by Method 537.1, to provide baseline PFAS leachate concentrations. Cuttings from the soil borings were returned to the ground surface within the planned excavation areas, and the boreholes were sealed with bentonite.

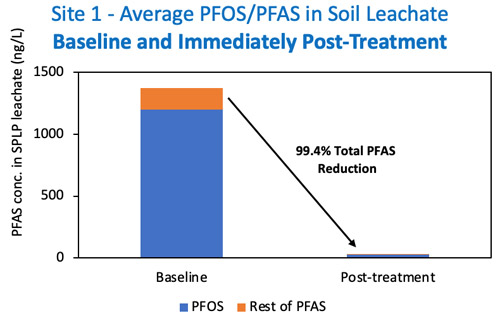

The baseline sampling results revealed average/maximum PFAS concentrations in soil leachate of 1,376/3,835 nanograms per liter (ng/L) at Site 1 and 7,079/16,115 ng/L at Site 2. PFOS (perfluorooctanoic acid) comprised approximately 90% of the total PFAS detected at both sites.

Application

Source soils were excavated from the target treatment area and temporarily stockpiled on the adjacent ground surface at each pilot test location. The topsoil layer was segregated for later use during site restoration.

After reaching the bottom excavation depth (10 ft bgs), a base layer of SourceStop solution was spray-applied to evenly coat the excavation bottom and sidewall bottom edges, allowing the material to infiltrate the underlying undisturbed soils before replacing the excavated soils. This process formed the SourceStop horizontal barrier base layer.

Once the barrier was in place, stockpiled soil was placed back into the open excavation in horizontal lifts, ranging from 2.5 to 4 feet thick, along with a prescribed carbon amendment blend. These materials were thoroughly mixed into the soils using the excavator bucket or a rotary mixing head until achieving a homogeneous consistency. Soils within the treatment area were turned multiple times before moving to the next lift to ensure complete treatment. Each completed lift was graded flat and compacted with a small trench compactor.

During the treatment process, representative samples were collected from treated test cells and analyzed for PFAS leachate in soil per the above-described laboratory methods to provide a snapshot of ‘immediate’ efficacy. Following treatment, the site work area was restored using the segregated topsoil vegetation as the final surface cover, which was re-seeded, and protected with straw erosion control matting.

The beginning of soil excavation.

The beginning of soil excavation.

SourceStop barrier base layer application.

SourceStop barrier base layer application. Completed SourceStop barrier base layer application.

Completed SourceStop barrier base layer application. Replacement of first lift of excavated soil.

Replacement of first lift of excavated soil. A rotary mixing head is used to blend PAC with soils.

A rotary mixing head is used to blend PAC with soils. Final surface grade with excess amended soils spread beyond the treatment limits to reduce mounding.

Final surface grade with excess amended soils spread beyond the treatment limits to reduce mounding.Application Details - Site 1 - MI

Treatment Area |

225 square feet |

Treatment Depth |

0 to 10 ft bgs |

Soil Volume Treated |

84 cubic yards |

Max. Total PFAS in Leachate |

3,835 ng/L |

Surficial Geology |

Sand, topsoil cover |

Implementation Date |

September 2022 |

SourceStop-PAC Blend Applied |

12,800 lbs |

Application Details - Site 2 - WA

Treatment Area |

225 square feet |

Treatment Depth |

0 to 10 ft bgs |

Soil Volume Treated |

84 cubic yards |

Max. Total PFAS in Leachate |

16,115 ng/L |

Surficial Geology |

Silty, clayey sand, topsoil cover |

Implementation Date |

January 2023 |

SourceStop-PAC Blend Applied |

9,200 lbs |

Results

For both pilot tests, samples were collected in designated test cells within hours after treatment and analyzed for PFAS in soil leachate before backfilling. At Site 1, six-month (March 2023) post-treatment samples were collected from the baseline sampling locations using the sampling and analysis procedures described above. The results observed at each site are described as follows.

Site 1 - MI

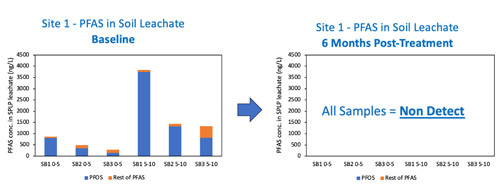

PFAS concentrations in soil leachate were immediately reduced (i.e., within hours) by 99.4% (Figure 2). After six months, no PFAS were detected. The laboratory detection limits for all compounds were less than 1 ng/L for these samples, demonstrating a 100% PFAS removal efficiency (Figure 3).

Figure 2. Site 1 PFOS and remaining PFAS concentrations in soil leachate at baseline and immediately post-treatment (<2 days).

Figure 2. Site 1 PFOS and remaining PFAS concentrations in soil leachate at baseline and immediately post-treatment (<2 days). Figure 3. Site 1 PFOS and remaining PFAS concentrations in soil leachate at baseline and after six months from samples collected in target treatment zone. PFAS detection limits for all PFAS are less than 1 ng/L.

Figure 3. Site 1 PFOS and remaining PFAS concentrations in soil leachate at baseline and after six months from samples collected in target treatment zone. PFAS detection limits for all PFAS are less than 1 ng/L.Site 2 - WA

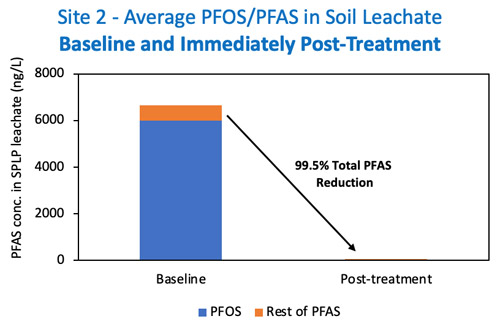

PFAS concentrations in soil leachate were immediately reduced by 99.5% (Figure 4). A six-month post-sampling event is scheduled for completion in the Summer/Fall of 2023.

Figure 4. Site 1 PFOS and remaining PFAS concentrations in soil leachate at baseline and immediately post-treatment (<2 days).

Conclusions

Vadose zone soils at or below the location of a PFAS release act as significant PFAS reservoirs at thousands of sites globally, presenting a long-term source of contamination long after the polluting events have ceased. The pilot tests completed at two prototype AFFF-release sites resulted in the immediate, complete, and sustained elimination of PFAS in soil leachate, demonstrating how these PFAS sources can be rapidly and effectively mitigated.

The in situ PFAS source treatments apply accelerated sorption kinetics to immediately halt PFAS contaminant plume development and prevent impacts to downgradient receptors. The SourceStop horizontal barriers emplaced at the base of the treatment zones significantly improve PFAS retention over commodity carbon materials like PAC, providing a highly effective, long-term solution to prevent PFAS leaching.

The sustainable remediation approach can be flexibly applied to vadose zone soils, the capillary fringe, and groundwater at PFAS source areas and tailored to meet site-specific conditions. SourceStop can be used as a standalone treatment or combined with PlumeStop® remediation in the plume body to enhance the attenuation of PFAS contaminant plumes and mitigate exposure risks.

Sustainable Remediation, defined by ISO 18504:2017, is the "elimination and/or control of unacceptable risks in a safe and timely manner whilst optimizing the environmental, social and economic value of the work."

These enhanced attenuation remedies replace non-sustainable remedial methods like dig & haul or pump & treat, which create more PFAS waste materials and generate greenhouse gases that further pollute the environment. REGENESIS Remediation Services now offers these in situ PFAS treatments as a turn-key service for deployment at AFFF-release and other PFAS source areas.