Best Practices for Translating In Situ Remediation Design into Field Success

Adapt to unpredictable site conditions by empowering skilled teams and leveraging modern equipment

Field technicians collaborate to ensure remediation projects adapt to on-site conditions.

In the in situ environmental remediation industry, much attention is given to selecting the right technology and developing an effective design. Yet even with the right technology and an optimal design plan, a project can still underperform. Why?

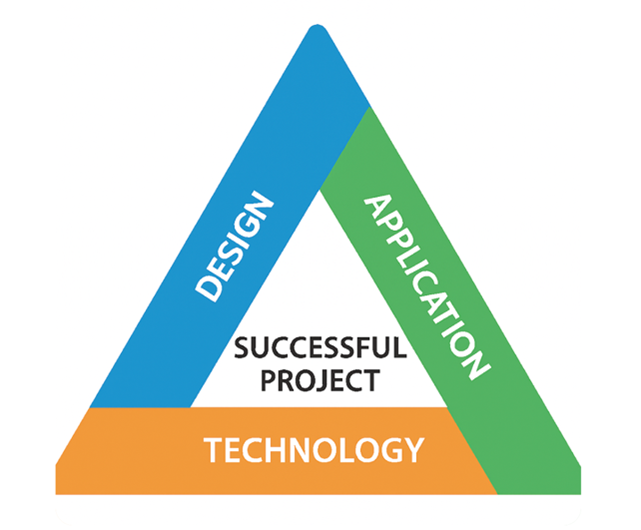

A successful remediation project requires the integration of three essential components: technology, design, and application. These elements form the sides of what can be visualized as a remediation triangle, with each side supporting the others. When all three are aligned and executed properly, the remediation project is positioned for optimal performance and long-term success.

TRIANGLE: The remediation triangle. (Image courtesy of REGENESIS)

While matching the right technology to the site conditions and designing its implementation to achieve cleanup goals are essential—and typically receive the most focus—field application can be just as important in determining a project's success.

When in situ remediation projects fall short, the root cause is not always the selected technology or the design itself, but how the remedy was applied. To minimize the risk of non-performance and improve the likelihood of achieving site goals, it’s essential to understand a few core principles and best practices for effectively applying in situ remediation technologies.

Know the Difference: Office Plan vs. Field Reality

Field application is where remediation plans meet the reality of subsurface conditions. Unlike a controlled laboratory environment or spreadsheet model, the subsurface is complex, dynamic, and full of surprises. Clay lenses, unexpected utilities, variable permeability, and seasonally shifting groundwater levels are just a few of the factors that can disrupt the original intent of a design—and negatively affect project outcomes.

Even with the right technology and a well-informed conceptual site model (CSM), success ultimately depends on how well the application adapts to these real-world challenges. When performance falters, it’s often because the application was treated as routine execution rather than an adaptive, real-time process.

Adopt a Dynamic Remediation Process

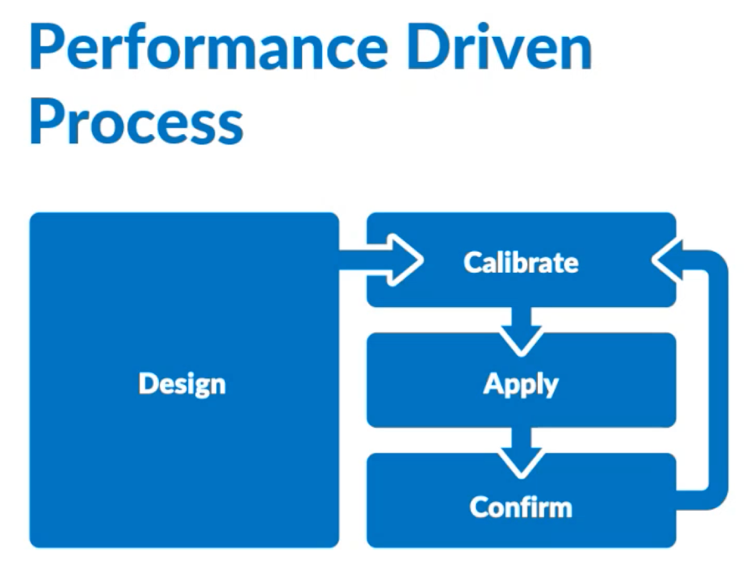

Adopting a dynamic remediation process—one that emphasizes continuous feedback, adjustment, and optimization during field implementation—is key to overcoming the challenges posed by the changing conditions encountered at virtually all sites. The following four steps define this process.

- Step 1 - Design Integration: This step begins with integrating the design for application readiness. It’s where collaboration with the design team helps align goals and anticipate field variables. A thorough understanding of the CSM, including the site's contaminant profile and lithology is essential, along with developing an injection strategy that includes built-in flexibility.

- Step 2 - Calibration: Pilot injections or small-scale tests are conducted to evaluate delivery rates, pressure thresholds, and reagent distribution. Field observations are compared against design assumptions, allowing for adjustments to dosing or delivery methods based on actual site response.

- Step 3 - Adaptive Application: The full-scale application is treated as an iterative process rather than a linear task. Field crews monitor pressures, flow rates, and injection volumes in real time and remain ready to relocate injection points, modify depths, or alter injection concentrations and amendment ratios as needed. Flexibility and responsiveness are critical during this phase.

- Step 4 - Confirmation: Piezometers or temporary wells are installed and samples collected to confirm the vertical and lateral distribution of amendments aligns with the design plan. The data collected during this step guide any further injections or adjustments needed to meet the project goals.

Steps 2 through 4 of this cycle—calibrate, apply, confirm—repeat throughout the application, ensuring real-time responsiveness to field conditions and supporting more effective outcomes (Figure 1). It is critical that clear, open communication in real-time be practiced through all these application steps.

Dynamic Remediation and Site Safety:

Importantly, field personnel who adopt a dynamic remediation mindset are better equipped to navigate unpredictable site conditions—reducing risk and improving safety outcomes. REGENESIS Remediation Services have completes over 1,000 applications annually, injecting over 15 million gallons of remediation amendments, while maintaining an industry-leading Experience Modification Rate (EMR), a key benchmark of workplace safety performance.

FIGURE 1: The dynamic remediation approach relies on a continuous cycle of calibrating, applying, and confirming to adapt to real-time field conditions. By integrating design insights with on-site observations, this iterative process helps ensure that application strategies remain aligned with project goals and evolving site realities. (Image courtesy of REGENESIS)

Figure 1: Dynamic Remediation - A Performance Driven Process. The dynamic remediation approach relies on a continuous cycle of calibrating, applying, and confirming to adapt to real-time field conditions. By integrating design insights with on-site observations, this iterative process helps ensure that application strategies remain aligned with project goals and evolving site realities.

Choose Field Teams Who Understand the Science

Field crews implementing an in situ application should be more than operators—they should be trained remediation professionals. When personnel understand the chemistry, geology, and system behavior they’re working with, they can make informed decisions that protect and enhance outcomes. Key competencies for field teams include:

- Geologic interpretation (e.g., recognizing permeability changes)

- Chemistry handling and mixing (e.g., pH-sensitive materials)

- Injection influence testing, data synthesis, and interpretation (e.g., confirming lateral and vertical distribution of amendments)

- Communication with stakeholders (e.g., discussing in-field changes transparently)

Perhaps most importantly, these individuals must be empowered to adjust the plan, not simply execute it.

Anticipate Changes

Every remediation project faces unexpected challenges—many of which require adjusting the original design plan. Utilities may block access to planned injection points. Injection pressures can spike without warning. Reagents might daylight or fail to reach the intended intervals.

In practice, the pieces don’t always fit as designed. At multiple sites, underground utilities force the repositioning of a permeable reactive barrier (PRB) downgradient of the original monitoring well network intended to measure its performance. In some cases, applications are delayed until new wells are installed to ensure that the remedy can be properly evaluated.

Adjustments like these are common—which is exactly why it’s critical to work with field teams who understand how design meets reality. When implementation is aligned with actual site conditions, projects stay on track.

The most effective field teams anticipate these curveballs and come prepared to adapt. This includes:

- Bringing redundant injection tooling and backup equipment

- Designing “floater” injection points to allow for real-time flexibility

- Maintaining open lines of communication with design engineers

- Logging detailed field observations to inform on-the-fly decisions and future work

In in situ remediation, adaptability in the field isn’t a backup plan—it’s a core part of executing the design.

Leveraging Equipment, Data, and Built-In Safety

Modern remediation application systems offer more than just precision—they also deliver critical safety features that protect workers and minimize risk during injection activities. Today’s field equipment is designed to improve both performance and safety, supporting best practices through:

- Positive displacement pumps for controlled, metered reagent delivery

- Automated flow and pressure sensors to monitor real-time subsurface response and prevent over-pressurization

- Inline blending systems that mix reagents on demand, reducing human error and limiting exposure to concentrated chemicals

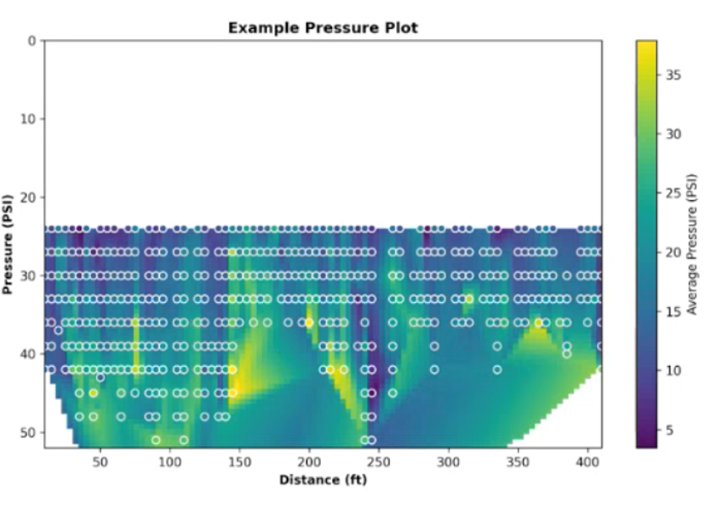

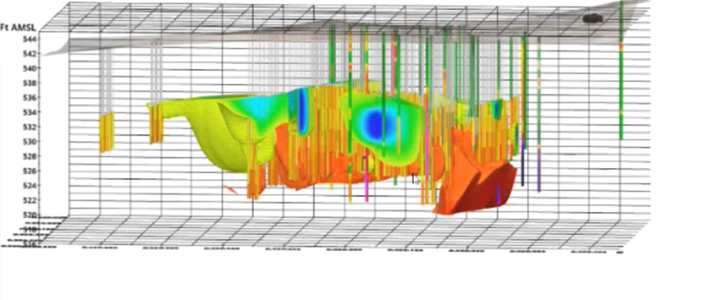

- Data logging and visualization tools that allow operators to track injection metrics and respond quickly to unexpected conditions

- Pressure relief valves, spill containment systems, and backflow prevention mechanisms integrated into most setups to enhance worker safety and environmental protection

The ability to collect and act on these data—during and after application—not only improves field adjustments and post-project evaluation but also helps maintain a safe, controlled injection environment from start to finish.

Report with Purpose: Validate, Visualize, Improve

A comprehensive summary report is more than a requirement—it’s a learning tool. Effective reports capture key information such as:

- As-applied injection locations and volumes

- Pressure and flow trends from injection logs

- Deviations from the original plan and the rationale behind them

- Maps showing GPS-located injection points, utilities, and site features

- Data and interpretations from soil and water samples assessing amendment placement versus design targets

EXAMPLES: Examples of IBIS-supported data visualizations of application pressures during in-situ remediation in x-section and 3-D outputs. Blue represents low injection pressures while yellow and orange represent higher pressures. (Image courtesy of REGENESIS)

DEPLOYED: IBIS system deployed in the field: Real-time data collection and visualization tools enable adaptive, performance-driven remediation by capturing subsurface injection pressures and optimizing application strategy on site. (Image courtesy of REGENESIS)

These records do more than confirm that the work was completed as planned—they provide a valuable lens into how the subsurface responded. This insight can inform future design iterations, guide adaptive field strategies, and ultimately improve the performance of subsequent applications.

The Cost of Getting It Wrong

What is the cost of poor application? It might be a delayed closure, an extended monitoring period, or even a failed cleanup. These can lead to stakeholder dissatisfaction, increased liability, and wasted resources.

On the other hand, strong field execution:

- Increases the likelihood of achieving cleanup goals on time

- Minimizes the need for re-treatment or additional investigation

- Strengthens stakeholder trust in both the technology and the team behind it

Conclusion: Prioritize Application, Maximize Results

In situ remediation success is not just about chemistry or modeling. It's about execution. It's about people who understand the science, technology that tracks the process, and a mindset that expects the unexpected.

As an industry, we must elevate the importance of field application. The best designs in the world will only succeed if they are implemented with care, flexibility, and expertise.

When we elevate field application to the level of science, we raise the standard for what remediation success looks like.

.webp?height=200&t=1668433096&width=200)